Impact pioneered the science of Wellbore Shielding®, the proprietary chemistry at the core of our FLC® and STAR SHIELD® fluid additives and SHIELD BOND® cement spacers. Traditional approaches to wellbore instability focus on remediation after fluid loss and formation damage begin. Our preventative approach reduces non-productive time and total well costs while helping to increase ultimate recoveries.

Shielding particles in our additives and spacers form an ultra-low permeability barrier at the fluid/rock interface. This thin, flexible “shield” minimizes fluid and pressure invasion in fragile and fractured formations, quickly sealing pore throats and microfractures to:

In reservoir drilling applications, Wellbore Shielding helps to enable unobstructed production flow throughout the life of the well. The shielding barrier:

FLC and STAR SHIELD products have enabled trouble-free drilling in basins around the world, including some of the most unstable, mechanically weak formations.

Watch how our Wellbore Shielding technology works in the fluid system.

FLC PRODUCTS STAR SHIELD PRODUCTS

STAR SHIELD PRODUCTS

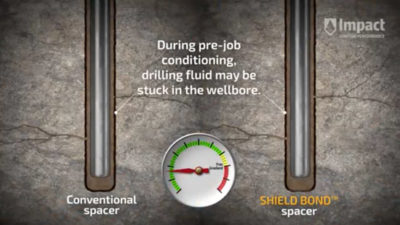

SHIELD BOND® is specially formulated to allow cement circulation to the programmed top of cement (TOC) where the equivalent circulating density (ECD) window is tight, or in fragile and fractured formations.

Discover SHIELD BOND spacers built on Wellbore Shielding technology.

SHIELD BOND PRODUCTS

Scientifically advanced Wellbore Shielding solutions demand an equally innovative software package to deliver peak performance and efficiency. Impact’s exclusive SimShield® suite models your well program using our FLC, STAR SHIELD and SHIELD BOND products to ensure optimal application.

PLAN YOUR PROJECT