This white paper summarizes a technical paper presented at the Offshore Technology Conference Asia, Kuala Lumpur, Malaysia,

27 February – 01 March 2024.

The oil and gas industry’s commitment to promoting sustainability has catalyzed the search for groundbreaking solutions capable of significantly reducing the carbon footprint and costs associated with field operations. In a paper presented at the recent OTC Asia conference, Impact Fluid Solutions—along with co-authors Pemex, Schlumberger and CSA Ocean Sciences—explores an innovative strategy for tackling these challenges within drilling operations. Central to our approach is the integration of Impact’s proprietary Wellbore Shielding® technology, an advanced drilling fluid additive that mitigates the environmental impact of drilling in multiple ways:

This approach is bolstered by a collection of case studies from diverse geographical locations, providing evidence of the technology’s efficacy in fostering more sustainable drilling practices. If deployed broadly across the oil and gas industry, our approach could usher in a new era of more sustainable drilling operations, helping energy companies align operational practices with global sustainability goals.

In December 2023, CSA Ocean Sciences released a report entitled “Emissions Calculations – Phase 1: Generalized Assessment for Three Drilling Scenarios.” This report represented the culmination of the first phase of research to quantify the environmental benefits of Impact’s drilling fluid additives.

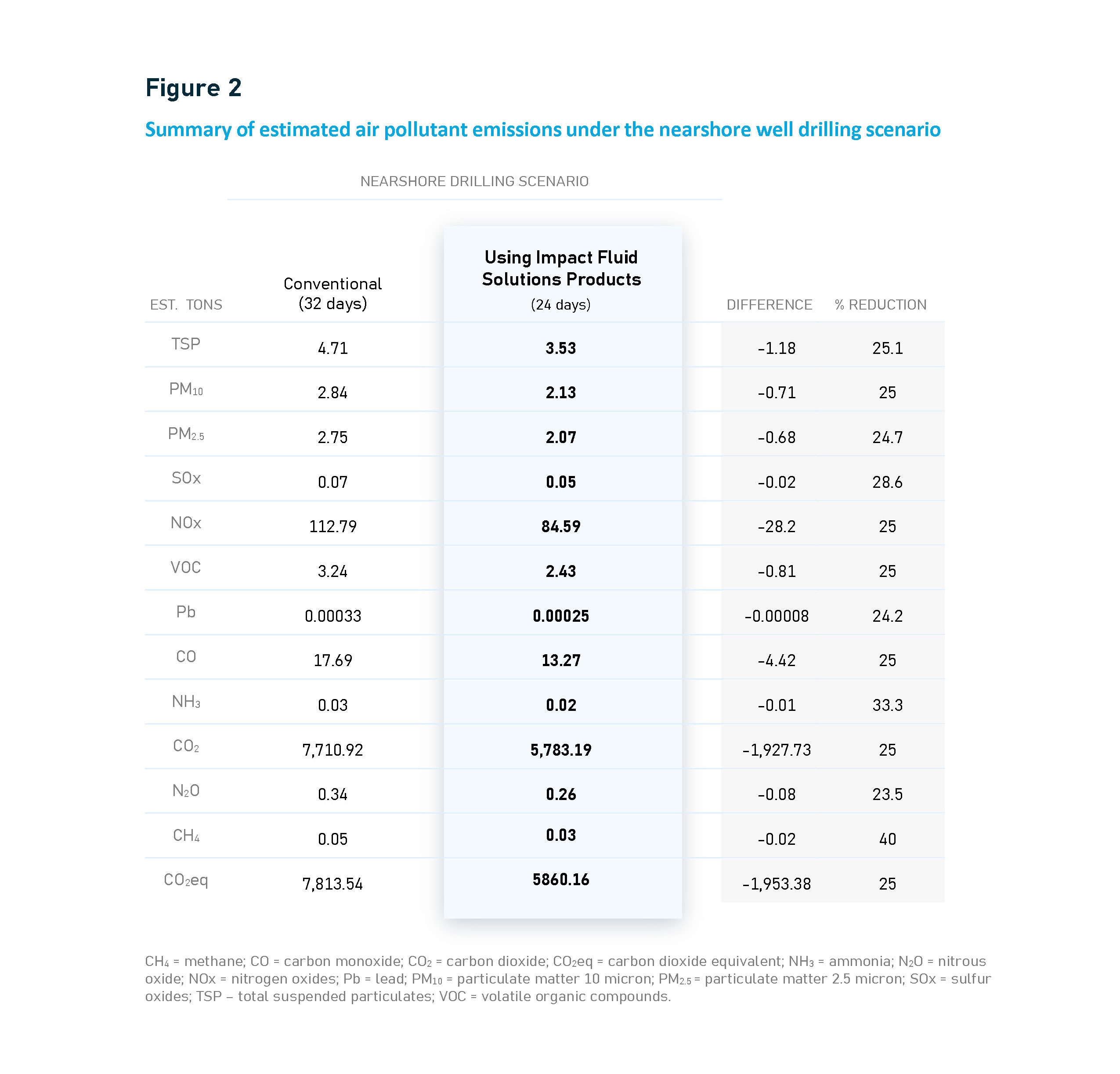

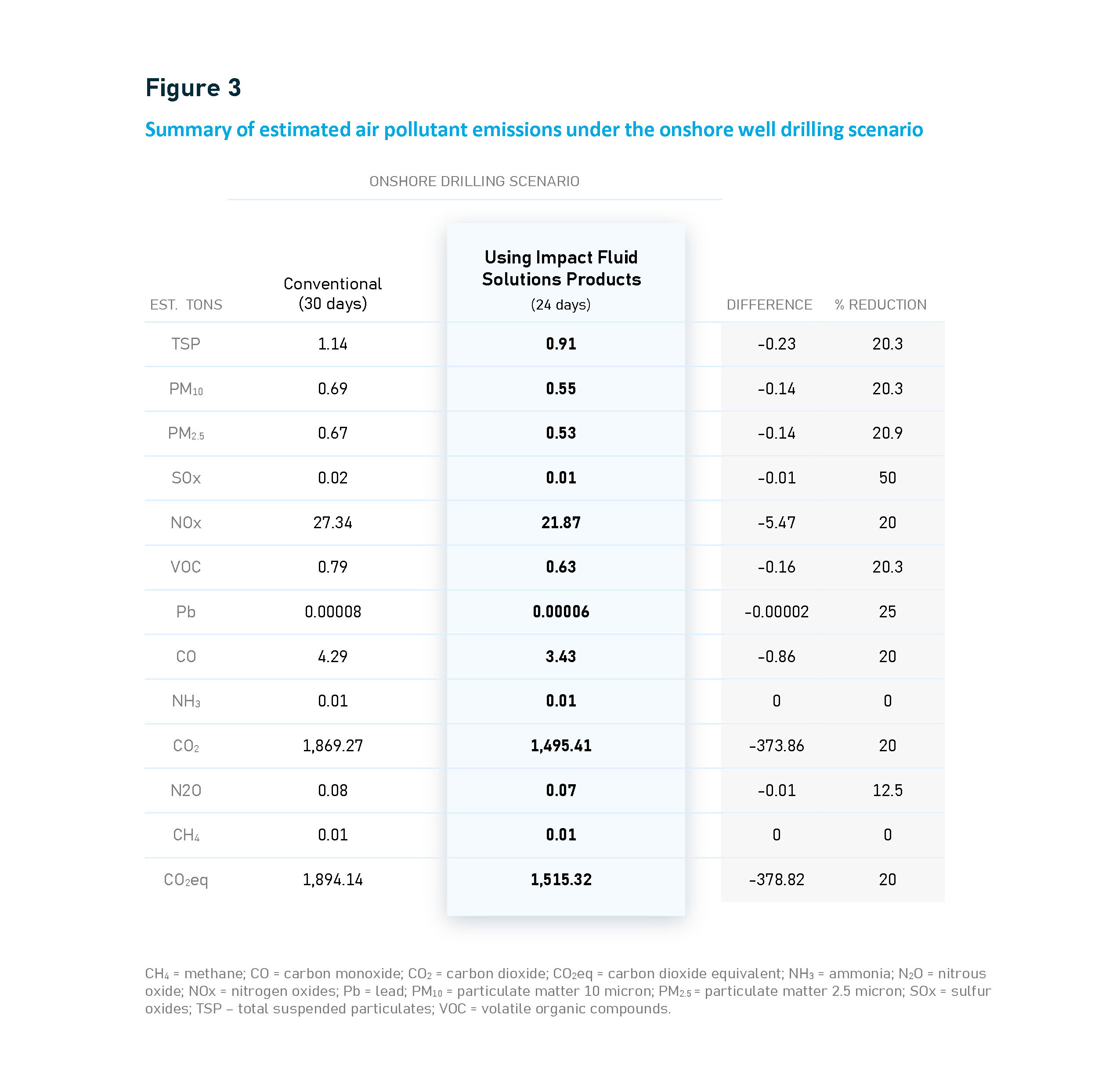

That phase focused on a comprehensive analysis of the carbon footprint resulting from three distinct oil and gas drilling scenarios: offshore deepwater wells, shallow water nearshore wells, and onshore wells. CSA Ocean Sciences identified key contributors to overall greenhouse gas (GHG) emissions across these scenarios, drawing upon the Bureau of Ocean Energy Management’s (BOEM) Gulf of Mexico Air Emissions Calculations Spreadsheet, Form-0138. Emissions were calculated based on drilling rig engine horsepower and fuel usage, with a focus on carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O) emissions. The assessment revealed that using Impact’s Wellbore Shielding® technology can reduce GHG emissions significantly—by approximately 24% on offshore wells, 25% on nearshore wells, and 20% on onshore wells—primarily by reducing drilling time. Impact’s Wellbore Shielding® technology was also shown to reduce chemical usage by 34% per well.

The Wellbore Shielding® technology at the center of CSA Ocean Sciences’ report on decarbonizing drilling fluids works by temporarily sealing freshly drilled rock to prevent fluid and pressure invasion. The thin yet robust shield deposited on the face of the wellbore expands the operating window, minimizing formation damage and fluid loss. This reduces both drilling time and the need for drilling fluid, which has been identified as a significant contributor to carbon emissions in drilling operations. The protective barrier formed at the fluid/rock interface can also eliminate the need for an intermediate casing string. Reducing the need for drilling fluid and casing string in turn shrinks the carbon emissions required to manufacture these products and transport them to the wellsite. Additionally, Wellbore Shielding® reduces the carbon footprint of drilling operations because the technology consists primarily of agricultural waste and not mined materials, which comprise most drilling fluid products.

The OTC paper highlights several case histories that illustrate the effectiveness of Impact’s Wellbore Shielding® technology across different geographical locations and operational scenarios:

This paper illustrates how Wellbore Shielding® technology significantly enhances both operational efficiency and cost savings while offering a lower-carbon alternative to conventional drilling fluid products and minimizing formation damage. The technology was shown to provide a 20-25% decrease in CO2eq emissions, depending on the location of the wellsite, from reduced rig time alone. Additionally, by reducing both chemical usage and casing requirements, the technology effectively decreases emissions throughout the logistics and supply chain. This marks a pivotal advancement toward more sustainable drilling in the oil and gas industry, and the technology’s promise for broader GHG emission reductions—pending further research—suggests a transformative potential.

In summary, Wellbore Shielding® technology is positioned as a critical innovation for the drilling sector, significantly diminishing environmental impact and bolstering efficiency and cost-effectiveness. This report projects the technology as a scalable answer to the industry’s sustainability hurdles, with future applications poised to further revolutionize environmental and operational practices.

To download the full technical paper, visit the OnePetro website.