The Suuk field, offshore Campeche, Mexico, is one of PEMEX’s priority development areas – complete with drilling challenges including transacting highly permeable sand zone stringers in the Middle Miocene. These stringers are known for total fluid loss, differential sticking, and NPT losses and were a problem in the nearby offset well. The challenge was to isolate the zone while drilling the 14½ x 17½ interval, prevent total loss of circulation, avoid differential sticking, improve ROP, and reduce drilling and operating time.

FLC® technology was chosen to seal the fractures and prevent fluid invasion from weakening the wellbore which would lead to further drilling issues. As a proactive treatment, the FLC 2000® technology was added at 8.82 lb/bbl (25 kg/m3). In addition, a pill with 8.82-lb/bbl (25-kg/m3) FLC EXTREME sealant was pumped for each stand drilled. At total depth, a 500-bbl (80 m3) pill with 0.5 lb/bbl (60 kg/m3) of FLC EXTREME was pumped prior to running casing.

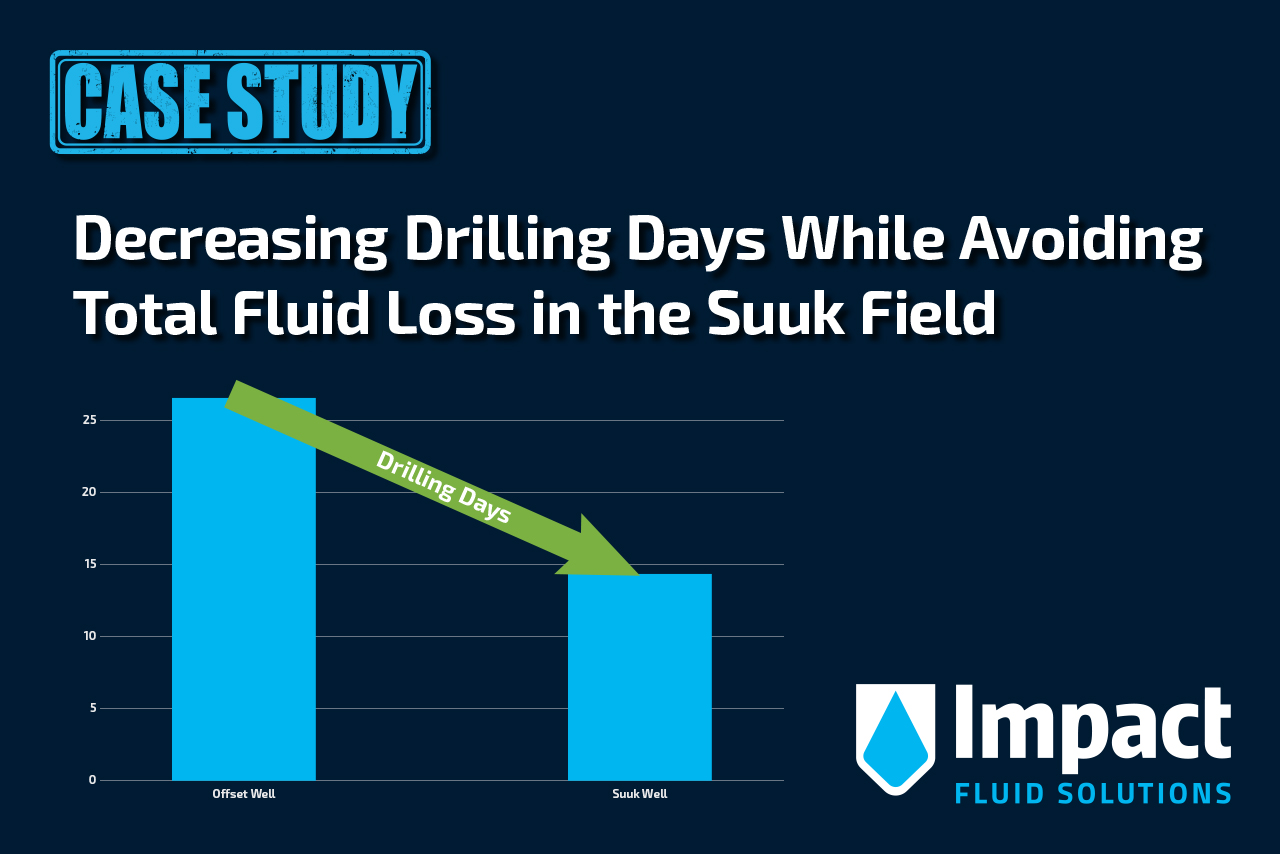

The well was drilled from the beginning of the trouble zone to final depth with no hole problems and minimal losses. Use of Impact Fluids’ products improved the wellbore stability issues, thus preventing total or massive losses. The improved overall ROP performance reduced the rig days from 27 (offset well) to 14 (Suuk well). The total cost from the beginning of the trouble zone to depth was over 40% less than the nearby offset well.