Challenge

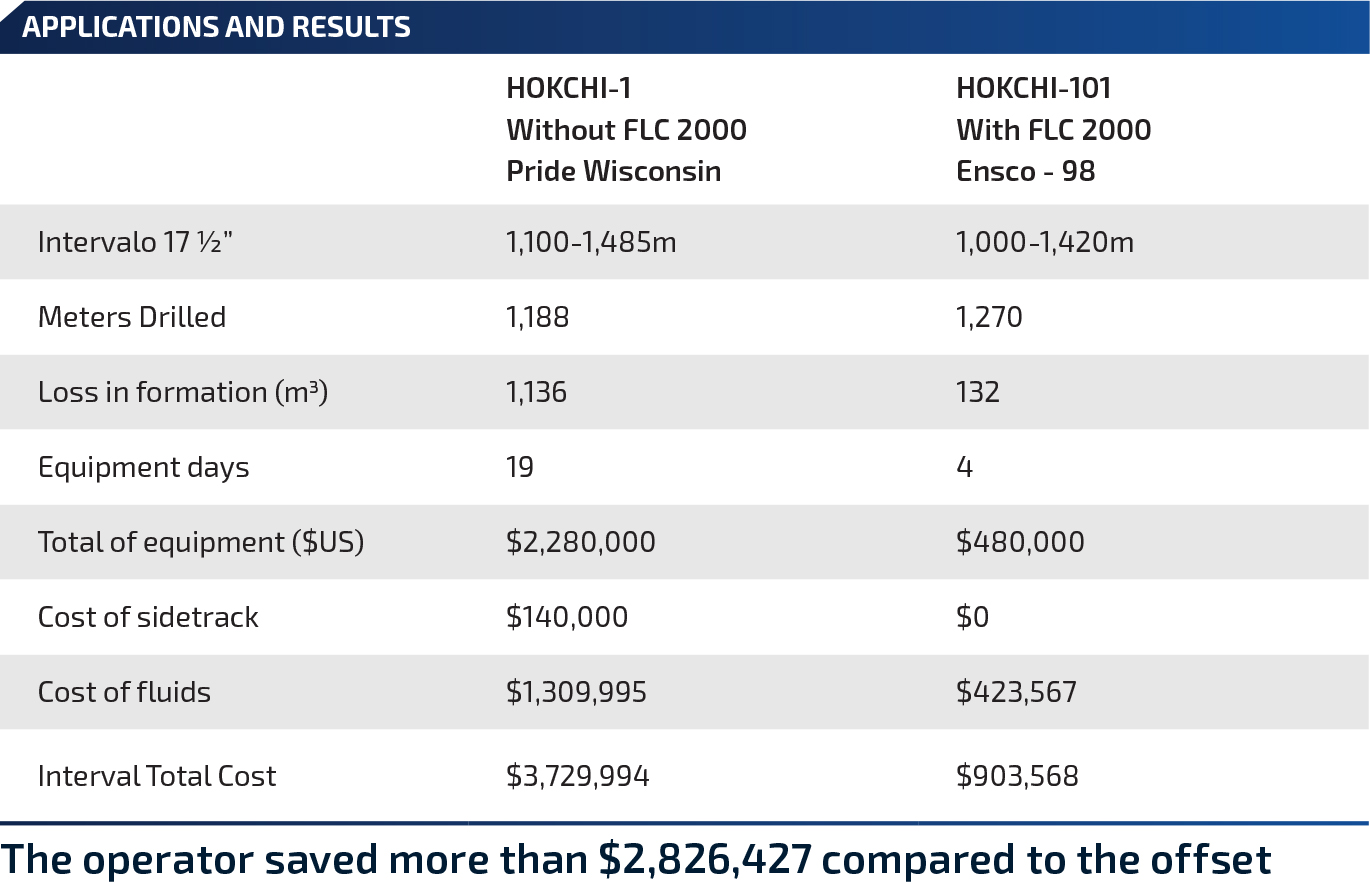

In the 17 ½-in. section of the HOKCHI-1 (offset) well, an operator experienced lost circulation and gas influx. The HOKCHI-1 well also reported differential sticking, and torque and drag issues, delaying drilling operations and increasing non-productive time (NPT). A cement plug was placed, and sidetrack drilled after several days of NPT.

Solution

The operator added FLC 2000 to the drilling program for the new HOKCHI-101 well. FLC 2000 was used to prevent drilling fluid related issues experienced with the previous HOKCHI-1 well, with the intent to reduce drilling days, loss of fluid, total well costs and other wellbore instability issues.

Results

During the 19 days of drilling of the offset well HOKCHI-1, 11 days were spent battling lost circulation and placing cement plugs. By applying FLC 2000 to the new well, costs were reduced by more than $2,000,000 by reducing drilling days over 80% (19 to 4). The casing was ran successfully to total depth (TD) with no issues.