Operators worldwide depend on FLC® Wellbore Shielding® additives to deliver problem-free drilling in depleted and mechanically weak formations. Unlike products used to remediate losses, these preventative solutions preserve wellbore stability throughout the drilling process.

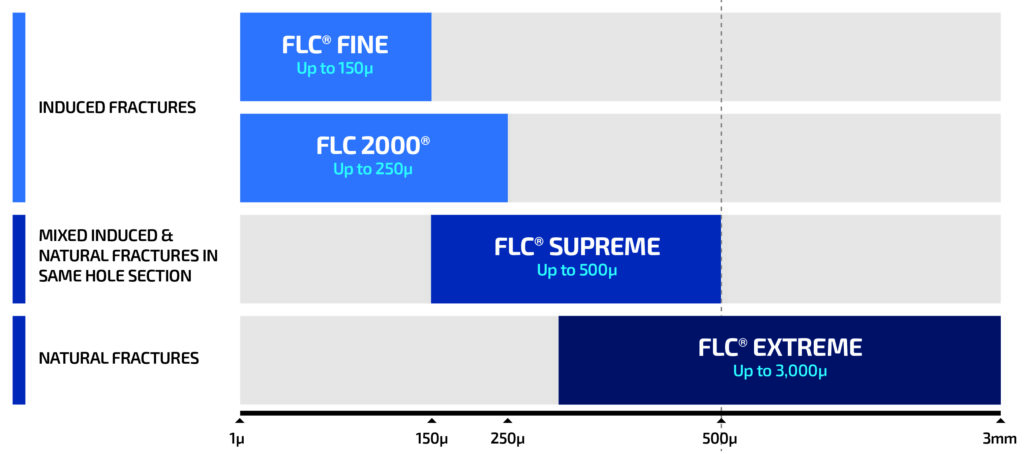

Compatible with all drilling fluids, FLC additives work with mud solids to quickly generate an ultra-low invasion barrier on the face of the formation, sealing pores and microfractures up to 100-3,000 μm to:

In reservoir applications, drilling fluids formulated with FLC additives help to optimize production potential by minimizing pay zone damage and providing high return permeability. When production is initiated, the inflow of the well lifts off the thin external filter cake with minimal differential pressure, eliminating the need for acid washes.