Mechanically weak shale and friable coal seams are common challenges encountered when drilling in offshore Malaysia. The Malong Field with formations such as the J and K shale (of the Miocene era) are intermingled with brittle coal seams of varying thickness. The depleted of I35, J15 and K5 sandstone are difficult to drill as well. The J and K shale and the coal seams require a minimum mud density of 10.5 – 11.5 lb/gal for wellbore stability and well control, but at these mud weights, the overbalance pressure for drilling the lower depleted sandstone section range from 700 – 1000psi depending on total depth (TD). As this section is drilled near horizontal orientation the risk of differential sticking is very high. Prior wells experienced wellbore collapse while drilling the coal seams due to the fluid invasion, mud losses and differential sticking in the depleted sandstone all at significant cost to the operator.

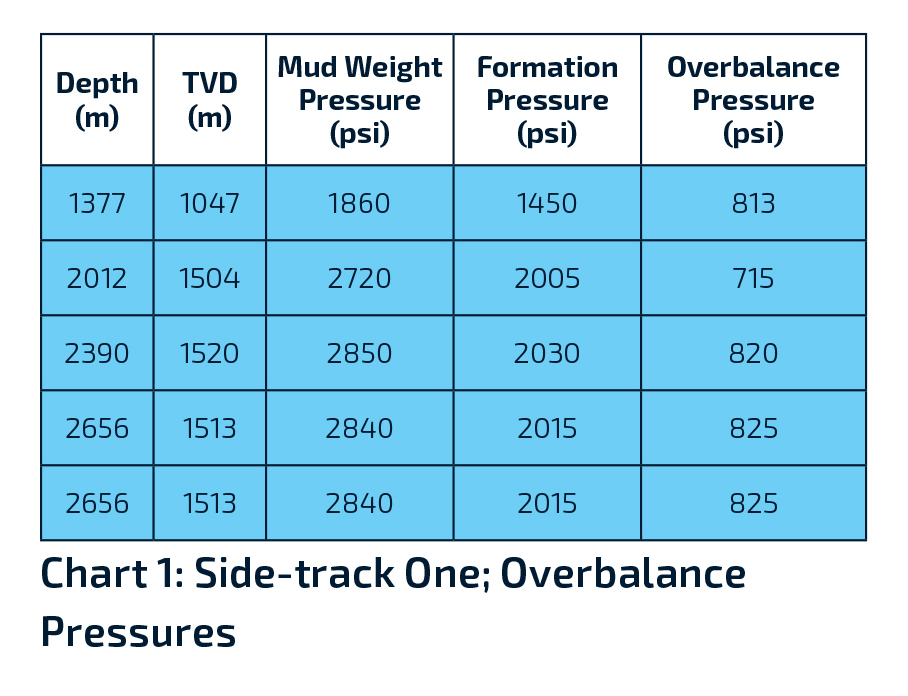

Two side-track wells with varying degrees of difficulty were successfully drilled through the production zone to TD using a synthetic-based mud system (SBM) with the addition of FLC 2000. Side-track One was drilled after a window was cut in the 13 3/8-in. casing at approximately 570 m (1,870-ft) and the new 12 ¼-inch open hole drilled to approximately 1000 m (3,280-ft)wherethe95/8-in.casingwasset. The well design included the shale formation with interbedded coal seams and depleted sandstones drilled as one section. This meant the higher mud weight of 11 lb/gal (2840 psi Mud Weight Pressure) required to drill the shale and coal seams was also subjected to the depleted sands. The 8 ½-in. section was drilled to TD at 2,656 m (8,710-ft) without losses or differential sticking in the depleted sands and the wellbore was stable and slick while tripping in and out of the hole through the coal seams and the shale.

The section length, over 600 m (1,968-ft.) of horizontal depleted sandstone was drilled without any mud losses or differential sticking. The use of 4 lb/ bbl FLC 2000 in the SBM system helped to protect the wellbore and the production zone and successfully complete the well.

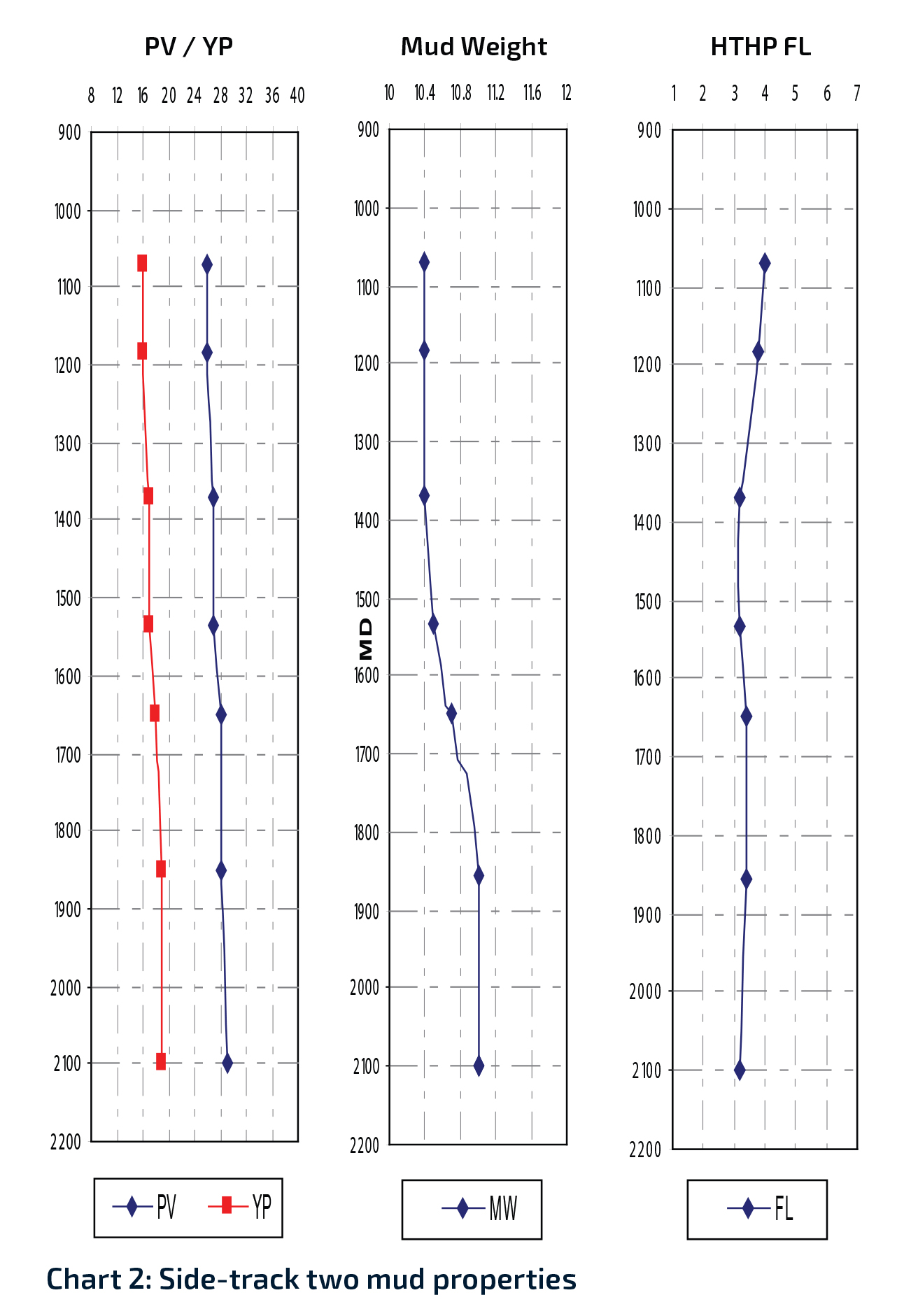

Side-track Two was very similar to the previous offset well where the mud weight window for drilling through the shale and coal was very tight to prevent high overbalance pressures through the depleted sandstone. During this side-track, the same mud from the previous side-track was used to drill the section. A maintenance dose of FLC 2000 was added to maintain the fluid properties. The 1100 m (3,608-ft) horizontal section was drilled without differential sticking or losses. The mud properties of the synthetic mud from the prior well remained robust, as presented in the graphs. As with the first side-track, there was a mud weight increase while drilling the depleted sandstone to ensure the shale and coal seams remained stable.

As more wells are drilled in mature fields like the Malong Field, depleted reservoirs carry greater risks of differential sticking and mud losses due to high overbalance and differential pressures. The mitigation of these high differential pressures creates a dilemma in the approach required to drilling these wells. The balance required to maintain wellbore stability and to mitigate the potential for differential sticking creates an operating window between pore pressure and formation failure that leaves very few options other than to redesign the well geometry and add extra casing strings. This can be a very expensive inclusion to the total well AFE. FLC 2000 has been designed to allow mud system to perform in these challenging environments, reducing the risk of wellbore stability problems, differential sticking and mud losses.