An operator planned to drill a mono-bore well design in the Woodford Shale in Oklahoma. Offset well data revealed this particular area in Canadian County typically experienced hole instability issues while drilling the production interval. Nearby offset wells lost over 3,000 barrels of oil-based mud (OBM) to the formation when drilling this section. Narrow pore pressure and fracture gradient windows added a challenge while drilling and setting casing. The drilling fluid design required sufficient mud weight to prevent gas influx. However, if the mud weight was too high it could lead to induced mud losses. Preventing both gas influx and mud losses was a challenge.

The operator adopted the use of STAR SHIELD for their mono-bore well design to prevent whole mud losses and provide wellbore stability while drilling the vertical, curve and horizontal sections to total depth (TD).

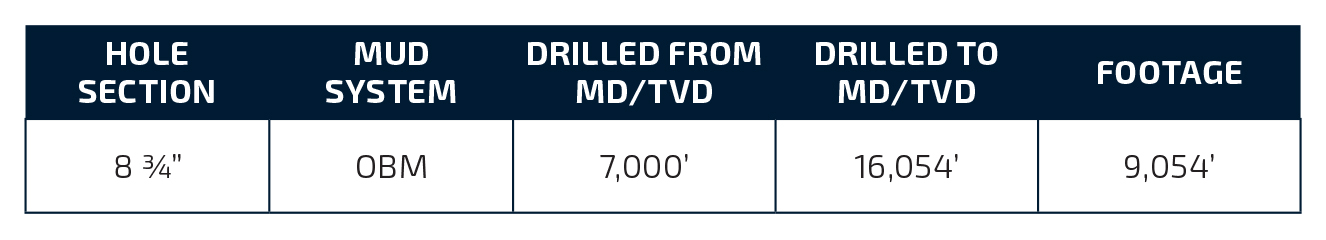

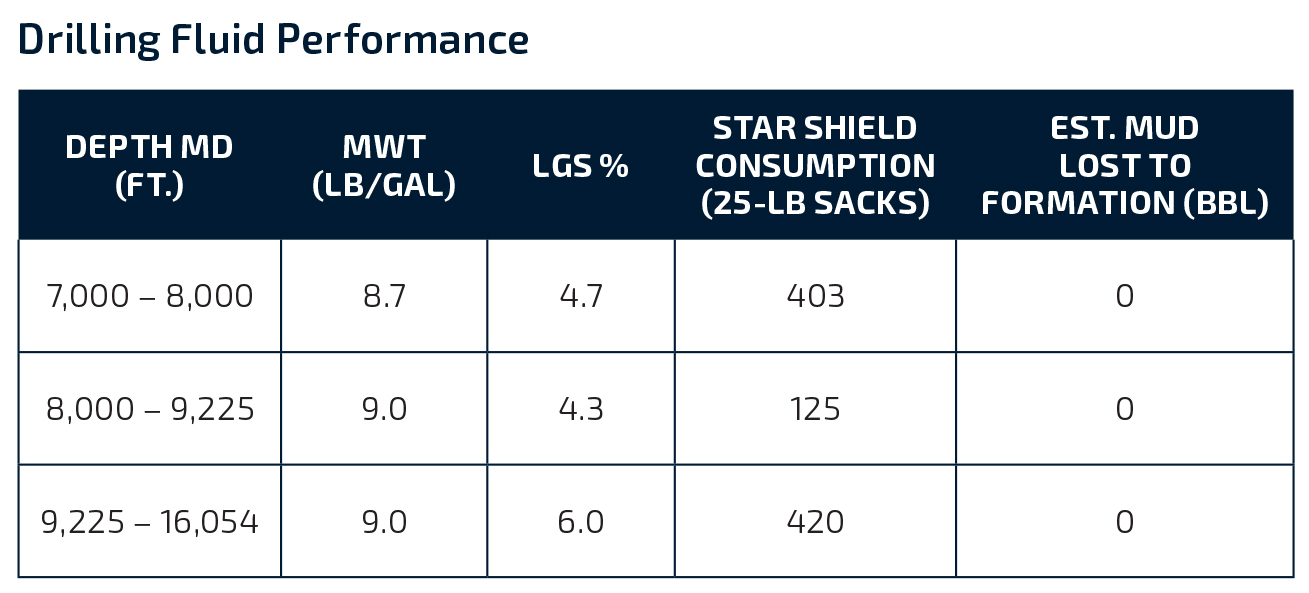

The OBM system was pre-treated with 9 lb/bbl of STAR SHIELD while drilling in the 8 ¾-in. vertical section (at 7,000-ft.). STAR SHIELD was added to the active circulating system while drilling in the 8 ¾-in. production interval and hourly treatments were maintained. The shale shakers were screened down to API 70s to prevent product discarding.

Once back on bottom with the curve assembly, STAR SHIELD additions continued while drilling through weak formations. The curve was landed at 9,225-ft. and a trip was made for the lateral assembly with no issues. Once back on bottom with the lateral assembly, STAR SHIELD additions continued while drilling the horizontal section to total depth at 16,054-ft., 8,598-ft. true vertical depth (TVD).

STAR SHIELD was used throughout the vertical, curve, and lateral sections from 7,000-ft. to TD (16,054-ft.) of the production interval with no whole mud losses and zero non-productive time (NPT). The critical concentration in the system ranged from 8-10 lb/bbl. The 5½-in. production casing was run without problem and was cemented at TD.