Challenge

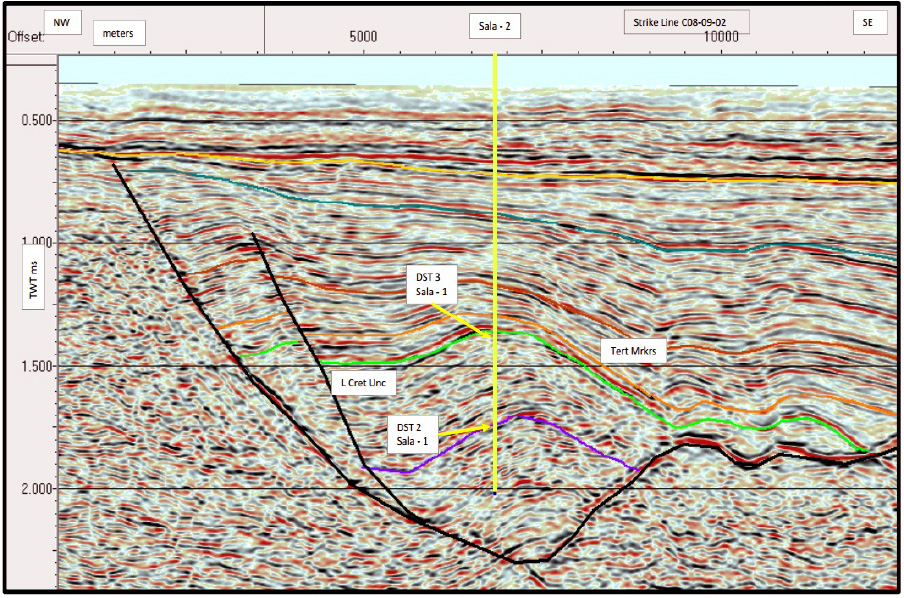

An operator planned to drill two appraisal wells in East Africa (Kenya) in a rift location with challenging geology. The lithology of the Graben formation where the drilling was planned included Cretaceous sands, porous sandstone mixed with shale interbeds. Prior appraisal wells had a history of tight hole, lost circulation, washouts, twist offs, cavings and hole collapse. The operator desired a cleaner hole to achieve better logs and test data retrieval.

Solution

The operator used an enhanced polymer water-based drilling on the two wells with a mud weight ranging between 8.8-9.3 lb/gal. After encountering wellbore stability issues on SALA-1, in both the 17 ½-in. and 12 ¼-in. sections, FLC 2000® was deployed in the 8 ½-in. reservoir section as good quality logs was critical.

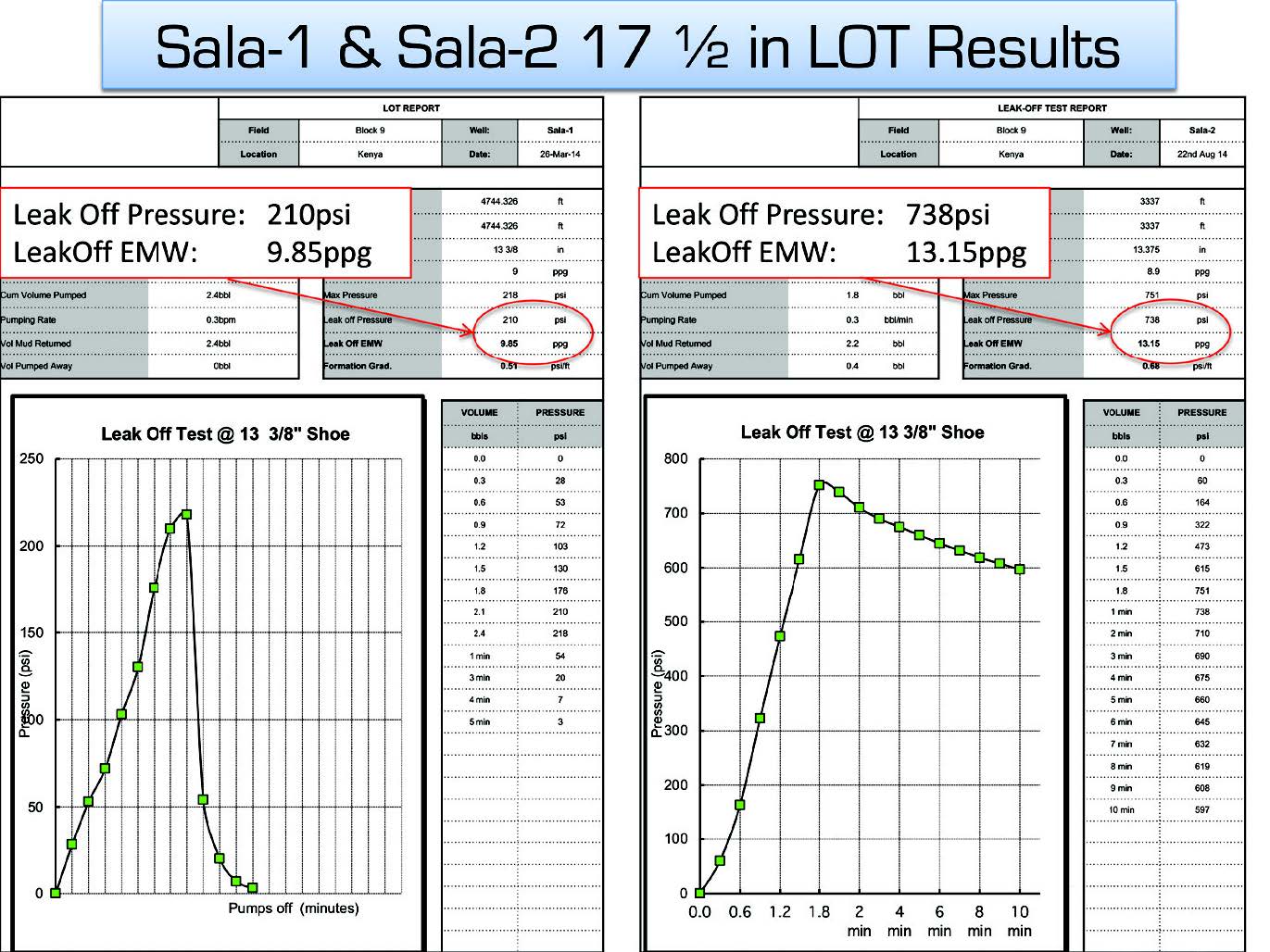

For SALA-2 the decision was made to have FLC 2000® added to the circulating system from the 17 ½-in. section onwards. The operator performed a leak off test (LOT) at 17 ½-in. casing shoe for both wells.

Results

In reviewing the two charts (SALA-1 – without FLC) and (SALA-2 – with FLC) note there is an increase in Leak off Pressure and Equivalent Mud Weight (EMW) attained in the well with FLC. The operator credits FLC 2000 with preventing formation breakdown in the SALA-2 well. The geometry of the curves also demonstrates that even when the well with FLC leaks off, it is not a catastrophic failure as it is with the other well, SALA-1 (i.e. no sharp pressure drop). The operator drilled a gauge hole with no indication of wellbore failure. The leak-off tests demonstrated the wellbore was able to hold higher pressures and mud weights compared to offset wells.